perma Automatic Lubrication Systems for Grease

Manual lubrication is labour- and time-consuming and impractical. It leads to a rapid aging of the lubricant in the bearing and causes the lubricant quality to fall exponentially. Bearings are then subjected to greater wear and even complete failure.

With automatic lubrication systems, the lubricant is discharged into the lubrication point at the right time, with the required quantity and optimal quality.

No contamination of lubricants occurs, because only the lubricant from the lubrication system is applied to the lubrication point.

Today, anyone looking for safe, effective and long-term economical lubrication of equipment takes advantage of automatic lubrication. perma offers an optimal solution for any lubrication point in terms of technology, economy, and workplace safety aspects.

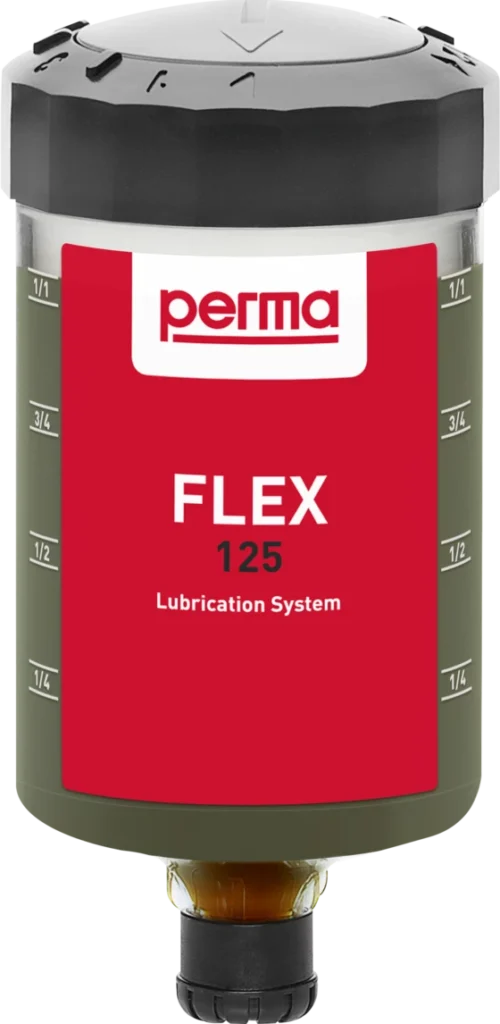

perma FLEX

perma FLEX is a single-point lubrication system for all types of applications and industries. Ingress protection to IP 68 level guarantees reliable lubrication in extremely dusty and moist environments. The wide operating temperature range makes it suitable for many applications indoors and outdoors. If necessary, the discharge period can be adjusted even after activation. It can be switched off during longer non-operation periods and is best used in the following equipment:

Conveyors

Pumps

Blowers / fans

Roller bearings

Sliding bearings

Open gears

Spindles

Shaft seals

Chains

The automatic lubrication system perma FLEX is available in two convenient sizes (60 cm³ / 125 cm³). It can be used for inside or outside applications at temperatures ranging from -20 °C to +60 °C. Discharge period setting is flexible and can be adjusted from 1 – 12 months using the dial on top of the lubricator.

perma FLEX comes fully assembled and ready-to-use. Simply turn the dial to the desired discharge period and the system is activated. The electronically controlled chemical reaction will build up the pressure that is necessary to continually supply the lubrication point with fresh lubricant.

- All-in-one system with rotary switch for discharge period setting

- Reliable operation at -20 °C to +60 °C

- Ex-proof certification, FM certification

perma FUTURA

perma FUTURA is suitable for single-point lubrication of roller- and sliding bearings, sliding guides, open gears, gear racks, spindles, shaft seals and chains. This lubrication system is ideal for areas that must be kept hygienically clean. Due to its resistance to corrosion it is especially suited for applications in the food industry. Here are other mechanical equipment that will last longer with perma FUTURA’s ALS:

Conveyors

Pumps

Roller bearings

Sliding bearings

Open gears

Spindles

Shaft seals

Chains

perma FUTURA is the ideal automatic lubrication system for areas that require hygiene or for harsh operating conditions which may lead to corrosion of metal lubricators or electronic systems. Its reliable operating principle is based on an electrochemical reaction. The lubrication period is determined by color coded activator screws. Depending on your application‘s requirement, you may choose to discharge 120 cm³ in a period of 1, 3, 6 or 12 months. The activator screw generates pressure (max. 4 bar) which moves the piston forward and continuously injects small lubricant amounts into the lubrication point.

- Simple activation with activator screw

- Transparent plastic housing with integrated support flange

- Ex-proof certification, Mining approval

perma CLASSIC

perma CLASSIC is a single-point lubrication system for roller- and sliding bearings, sliding guides, open gears, gear racks, spindles, shaft seals, chains, etc. operated at ambient temperatures that reach from 0 up to +40 °C. Typical applications can be found in mining, steel, automotive and mechanical engineering.

It is best suited for the following equipment:

Conveyors

Pumps

Roller bearings

Sliding bearings

Open gears

Spindles

Shaft seals

Chains

perma CLASSIC can be used for all applications with ambient temperatures of 0 to +40 °C. The reliable operating principle is based on an electrochemical reaction. The lubrication period is determined by color coded activator screws. Depending on your application’s requirement, you may choose to discharge 120 cm³ in a period of 1, 3, 6 or 12 months. The activator screw generates pressure (max. 4 bar) which moves the piston forward and continuously injects small lubricant amounts into the lubrication point. perma CLASSIC is fully dust and water proof and can withstand impacts and accidental knocks.

- Simple activation with activator screw

- Metal housing

- Ex-proof certification, Mining approval

perma STAR VARIO

perma STAR VARIO is used for single-point lubrication of roller and sliding bearings, sliding guides, open gears, gear racks, spindles, shaft seals and chains. Thanks to precise lubricant metering, perma STAR VARIO is ideal for lubrication of electric motors with specified lubricant quantities.

Its applications are best suited for the following equipment:

Conveyors

Pumps

Blowers / fans

Electric Motors

Chains

Shaft seals

Spindles

Open gears

Sliding bearings

Roller bearings

The automatic lubrication system perma FLEX is available in two convenient sizes (60 cm³ / 125 cm³). It can be used for inside or outside applications at temperatures ranging from -20 °C to +60 °C. Discharge period setting is flexible and can be adjusted from 1 – 12 months using the dial on top of the lubricator.

perma FLEX comes fully assembled and ready-to-use. Simply turn the dial to the desired discharge period and the system is activated. The electronically controlled chemical reaction will build up the pressure that is necessary to continually supply the lubrication point with fresh lubricant.

- All-in-one system with rotary switch for discharge period setting

- Reliable operation at -20 °C to +60 °C

- Ex-proof certification, FM certification

More Products

Should you require further information on other products and accessories from perma, please click here

For all further inquiries, please contact us.